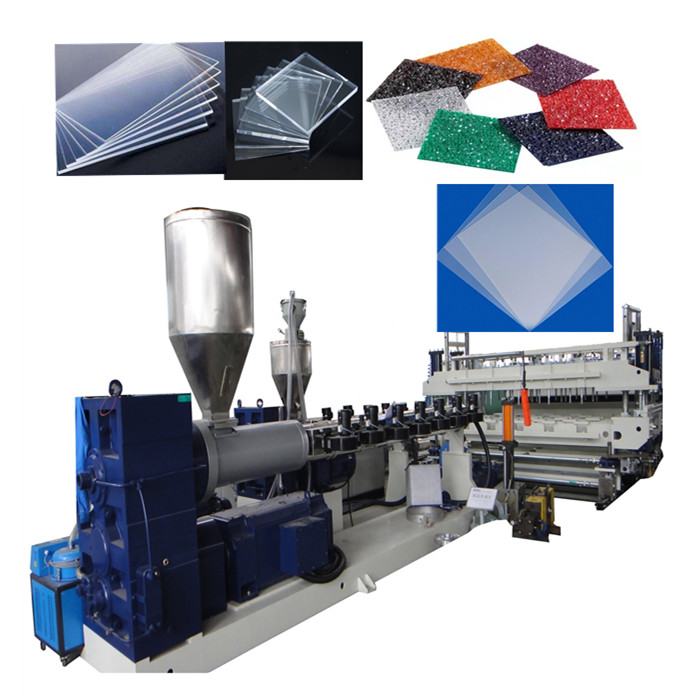

透明PC/PMMA/ABS板材挤出机

PMMA/ABS板材生产线技术配置

PMMA/ABS plate line technical specification

I.概述 general | |

1. 使用条件 Usage condition | 380V/3P/50Hz |

2. 使用物料 Suitable material: PMMA/ABS | |

3. 制品规格 Finished plate specification: L=1500mm,δ=2-4mm | |

4. 最大产量 Max. Output capacity: 400kg/h | |

II.设备清单 Equipment list | |

1. 单螺杆挤出机 | 2台 |

Single screw extruder | 2units |

2. 液压换网器 | 2台 |

Hydraulic Screen changer | 2units |

3. 计量泵 | 2台 |

gear pump | 2units |

4. 模具 | 1套 |

T-die | 1 set |

5. 三辊压光机 | 1台 |

Three-roller calender | 1 unit |

6. 冷却托架 | 1台 |

Cooling bracket | 1 unit |

7. 辊温控制器 | 1台 |

Roller temperature controller | 1 unit |

8. 牵引机 | 1台 |

Haul off unit | 1 unit |

9. 切割机 | 1台 |

Cutter | 1 unit |

10. 剪板机 | 1台 |

Guillotine | 1 unit |

11. 皮带输送机 | 1台 |

Belt conveyer | 1 unit |

12. 堆放台 | 1台 |

Stacker | 1 unit |

13. 电器控制系统 | 1套 |

Electric control system | 1 unit |

14. 上料干燥系统 | 1套 |

Loading and drying system | 1 unit |

III.详细技术配置Detailed technical specification | |

材质Material | 38CrMoAlA |

渗氮深度Nitrided layer thickness | 0.5-0.7mm |

螺杆硬度screw hardness | HV≥740 |

机筒硬度 barrel hardness | HV≥940 |

长径比 L/D | 38:1 |

螺杆直径 Screw diameter | 120mm |

机筒加热区 Heating zones for barrel | 8 zones |

总加热功率Total heating power | 80KW |

加热方式 Heating method | 陶瓷加热 Ceramic heating |

冷却方式 Cooling method | 风机冷却 Air cooling |

驱动 Drive | |

电机Motor | 直流电机DC motor |

调速器 Inverter | ABB |

电机功率 Drive Power | 160KW |

减速箱产地Gearbox origin | Made in China |

齿轮形式 Gears type | 斜齿轮 Helical gears |

热处理 Heat treatment | 渗碳磨齿 Carburized and grind |

电机与减速箱连接形式 Connection method of motor and gearbox | 直联式 Direct connection |

排气系统Vented system | |

真空泵功率Vacuum pump power | 11kw |

1.SJ75/38排气式单螺杆挤出机Vented single screw extruder | |

螺杆机筒screw and barrel | |

材质Material | 38CrMoAlA |

渗氮深度Nitrided layer thickness | 0.5-0.7mm |

螺杆硬度screw hardness | HV≥740 |

机筒硬度 barrel hardness | HV≥940 |

长径比 L/D | 38:1 |

螺杆直径 Screw diameter | 75mm |

机筒加热区 Heating zones for barrel | zones |

总加热功率Total heating power | 80KW |

加热方式 Heating method | 陶瓷加热 Ceramic heating |

冷却方式 Cooling method | 风机冷却 Air cooling |

驱动 Drive | |

电机Motor | 交流电机AC motor |

调速器 Inverter | ABB |

电机功率 Drive Power | 55KW |

减速箱产地Gearbox origin | Made in China |

齿轮形式 Gears type | 斜齿轮 Helical gears |

热处理 Heat treatment | 渗碳磨齿 Carburized and grind |

电机与减速箱连接形式 Connection method of motor and gearbox | 直联式 Direct connection |

排气系统Vented system | |

真空泵功率Vacuum pump power | 11kw |

2. 换网器Screen changer | 2 units |

液压换网器 hydraulic screen changer | 双工位单柱式,自动换网 double working place, column type, automatic changing 配液压站(最高压力16Mpa) equipped with hydraulic station (Max. pressure 16Mpa) |

3.计量泵Gear pump | |

产地 origin | Made in China |

250CC | For 120/38 extruder |

传动功率 drive power | 18.5KW |

3.1 | |

4.模具T-die | |

模具结构 structure of T-die | 衣架式流道 Clothes hanger type flow channel |

模具宽度 width of die | L=1800mm |

制品宽度 plate width | L=1600mm 带堵块/Die lip adjustable |

制品厚度 plate thickness | 1-6mm |

5. 三辊压光机/ Three-roller calender | |

辊筒直径 Roller diameter | Φ500mm |

辊筒材质 Roller material | 42CrMo合金钢alloy steel |

辊筒长度 Roller Length | L=2400mm |

表面粗糙度 Surface roughness | Ra≤0.016um |

表面硬度 Surface hardness | HRC55 |

镀鉻厚度 Chromium coated layer thickness | 0.08mm |

传动方式 Drive type | 独立传动Separate drive |

变频器 Frequency inverter | Yaskawa servo motor |

独立传动功率 Separate driving power | 2.9Kw×3 |

减速机传动 Transmission | FALK |

辊筒间隙调整 Gap adjustment between rollers | 采用液压升降,手动涡轮蜗杆调距 Open and close by hydraulic; Gap adjusted by worm wheel and worm manually |

带自锁功能,有安全急停开关,同步控制系统 With self-lock function, emergency stop button, synchronous control | |

液压电磁阀Hydraulic electromagnetic valve | Japan Yuken日本YUKEN |

三辊轴承 Bearings for three rollers | Japan NSK 日本NSK |

三辊形式 Calender type | 直立式下进上出Vertical (Down in Up out) |

旋转接头rotational joint | 台湾杨桄Taiwan Yangguang |

6. 辊温控制器 roller temperature controller | |

冷却介质 Cooling medium | 油 Oil |

温控范围 Temperature range | 35-170℃ |

温控精度 Temperature control precision | ≤±1℃ |

加热功率heating power | 3×18Kw |

热交换器heating exchanger | 3×8m2 |

油泵Oil pump | 杭州格兰富made in Hangzhou |

功率power | 3Kw |

电磁阀electromagnetic valve | 气动角座阀pneumatic vavle |

附有自动超压、超温、缺水等报警功能Be with alarm function | |

7. 空冷托架Cooling bracket | |

托架长度 Bracket length | 11m |

托辊 Rollers | 铝辊氧化处理,抛光 Aluminum rollers, oxidized, polished |

规格 Specification | Φ70×1800mm |

托架前段采用7根冷却定型镜面辊(规格为Φ120X2400mm, 通水冷却),带动力。 Front side use 7 mirror polish rollers with the driving motor(Size:Φ120X1800mm,water cooling) | |

正面反面双工位覆膜装置1套Upper and down two stations protection film lamination unit | |

8. 双牵引机Double Haul off unit | |

胶辊材质 Rubber roller material | 丁晴橡胶 Nitrile rubber |

规格 Specification | 4×Ф250mm×2400mm |

变频器 Frequency inverter | Yaskawa servo motor |

独立传动功率 Separate driving power | 2.9Kw×3 |

减速机传动 Transmission | Falk |

与三辊同步也可独立 It can be controlled synchronously with the three rollers or separately. | |

锯片切边装置Saw Side trim | 3组,可调距 3 uints, distance adjustable |

专用锯片电机special saw motor | 1.5kw,3200rpm |

变频调速frequency control | Danfoss Danmark |

进口合金钢锯片alloy steel saw(Import) | Ф350mm |

9.横向切割机landscape orientation Cutter | |

横向移动landscape orientation moving | 直线轴承beeline bearing |

纵向移动lengthways moving | 齿轮齿条传动,同步gear rack transmission,synchronization |

专用锯片电机special saw motor | 1.5kw,3200rpm |

切割程序Cutting Programs | PLC control / PLC控制 |

计长 length counting | 米轮编码器meter |

工作台纵向移动速度可调,横向切割的移动速度也可调,前后移动采用变频调速。 The lengthways moving speed of worktable can adjust,landscape also use frequency control | |

吸屑装置Saw dust suction device | 电机功率Fan motor 5.5kw |

采用高压低噪音风机,配整套硬软风管及集尘袋。 Use high pressure and lower noise fan motor,with soft or hard pipeline and collection bag | |

10. 皮带输送/升降台belt conveyor, stacker | |

皮带输送机belt conveyor | 1800mm×3000mm |

液压升降台 hydraulic stacker | 1800mm×3000mm |

11. 上料干燥系统Loading and drying system | |

1000Kg干燥机1台;800kg/h螺旋上料机2台 1000kgdrier 1 units, 800kg/h spiral loader 2 units | |

12. 电器控制electricity control | |

主要电气元件main electric components | |

操作屏screen | 西门子SiemensMP277 |

PLC | 西门子Siemens S7-200 |

主机调速器inverter for extruder | ABB |

接触器contactor | 西门子Siemens |

继电器breaker | 欧姆龙Omron |

低压断路器breaker | 施耐德Schneider |

空气开关air switch | LG |

按钮﹑开关指示灯buttons and indication lights | 施耐德Schneider |

显示表meter | 奥托尼克斯Autonics |

邮箱: tracyguan@hanhaisuji.com

邮箱: tracyguan@hanhaisuji.com